CAD denotes use of programs that replaces the pencil and assist the designers in the representation of ideas. These programs aid in the achievement of a quick development of the design and allow an immediate control.

One of the biggest trends the jewellery industry has seen in the last decade has been the rise of Computer Aided Design (CAD) in the jewellery world. There are two main reasons for using CAD instead of traditional handmade those are Speed, and accuracy.

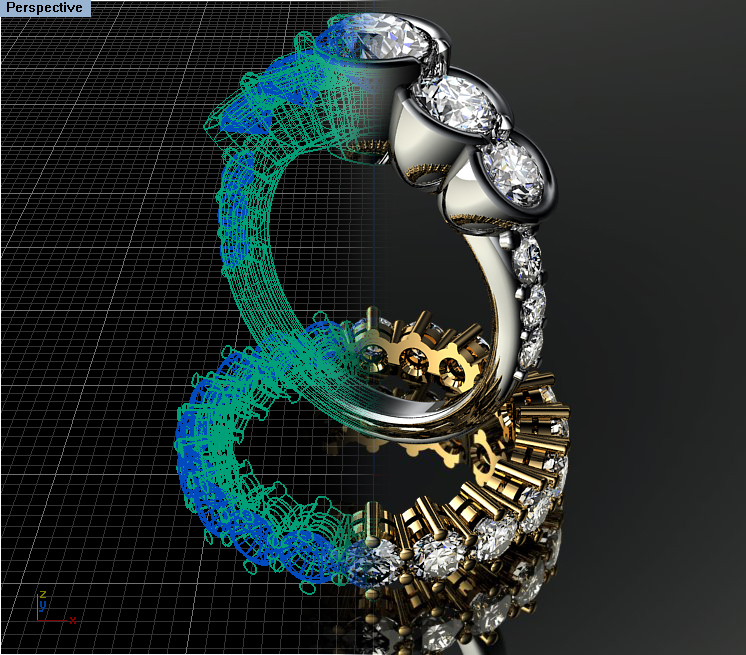

It offers the chance to have your design made in 3D; The image can be rotated and viewed from all angles [360°]. This allows for all proportions, dimensions, shapes and colours to be arranged or altered to get the look just right - no more hand drawn sketches and even a digitally rendered image or video of what the finished article will look like. If you would like something changed it is not a problem at all, we can tweak the design and send another image.

This all done without the manufacturing of jewellery in precious metal. Before our use of CAD, if a ring was made up, it was much more difficult to make adjustments to it!

The photo real quality of our CAD generated images gives you, the customer absolute confidence in committing to a piece without worrying about how many misunderstandings or confusion in buying an 'unseen' piece.

Many assume there is less skill involved with CAD; however it really does require a great amount of knowledge and experience, not just in operating a computer program, but making jewellery on the work bench the traditional way - this skill, knowledge and experience is something we are proud to have in abundance.

We at 3D JEWELS with designing technologies can help you in maintaining complete in-house control of your design - from concept to reality. You'll benefit from being able to design your jewellery using state-of-the-art jewellery design software being associated with us.

Together CAD/CAM allows the design of jewellery using a computer (CAD) and creates an exact hard copy model of a jewellery piece using a CAM machine.

Computer-aided masters (CAM) is the use of computer-based software tools that assist engineers and technicians in manufacturing or prototyping product components. CAM is a programming tool that allows the manufacturing of physical models using computer-aided design (CAD) programs. CAM creates real life versions of components designed with a software package. CAM technology not only allows direct control of machines and its functions, but can also enable production planning, in order to reach the following objectives:

By the way of CAM machining route is planned. The material used is not gold, more commonly, material used are such as wax, plastic or a base metal. With the help of CAD-CAM, jewellery manufacturers will be able to provide better quality at a speedy time and affordable cost.

CAD/CAM helps immensely in:

We offer reduced time and reduced cost for jewelry designers and their clients with state-of-the-art technology. We use all file types compatible with any CAM device, which allows us to quickly generate a precise wax model ready for casting. Our technicians have been in the jewelry business from long. They have been operating in various branches of the industry. We are some of the finest jewelry manufacturers and jewelers in the industry.

For an Efficient Production of Jewellery with Effective and Efficient output a Silicon Rubber Dye is the key. We at 3D JEWELS take care of all parameters which are required in Production and provide a Perfect Rubber Dye which will allow our Clients to take out numerous wax or plastic replicas of a model out of a single Rubber Dye in order to make Multiple Casting Pieces.

It offers the chance to have your design made in 3D; The image can be rotated and viewed from all angles [360°]. This allows for all proportions, dimensions, shapes and colours to be arranged or altered to get the look just right - no more hand drawn sketches and even a digitally rendered image or video of what the finished article will look like. If you would like something changed it is not a problem at all, we can tweak the design and send another image.

This all done without the manufacturing of jewellery in precious metal. Before our use of CAD, if a ring was made up, it was much more difficult to make adjustments to it!

The photo real quality of our CAD generated images gives you, the customer absolute confidence in committing to a piece without worrying about how many misunderstandings or confusion in buying an 'unseen' piece.

Many assume there is less skill involved with CAD; however it really does require a great amount of knowledge and experience, not just in operating a computer program, but making jewellery on the work bench the traditional way - this skill, knowledge and experience is something we are proud to have in abundance.

We at 3D JEWELS with designing technologies can help you in maintaining complete in-house control of your design - from concept to reality. You'll benefit from being able to design your jewellery using state-of-the-art jewellery design software being associated with us.